Table of Contents

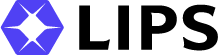

ToggleESG compliance deadlines are approaching faster than most logistics executives anticipated. The irony is striking: an industry that tracks packages across continents in real-time still relies on imprecise measurement methods that create unnecessary waste and hidden costs. Parcel dimensioning technology transforms this measurement gap into competitive advantage, delivering the precision that sustainable logistics operations demand.

Why Sustainability Matters in Logistics

According to McKinsey & Company, the logistics industry accounts for an estimated 7% of global greenhouse gas emissions a significant part of corporate supply-chain carbon footprints. With broader netzero targets and tighter ESG regulations, green logistics has transitioned from optional initiative to business imperative.

Four Ways Parcel Dimensioning Technology Drives Sustainability

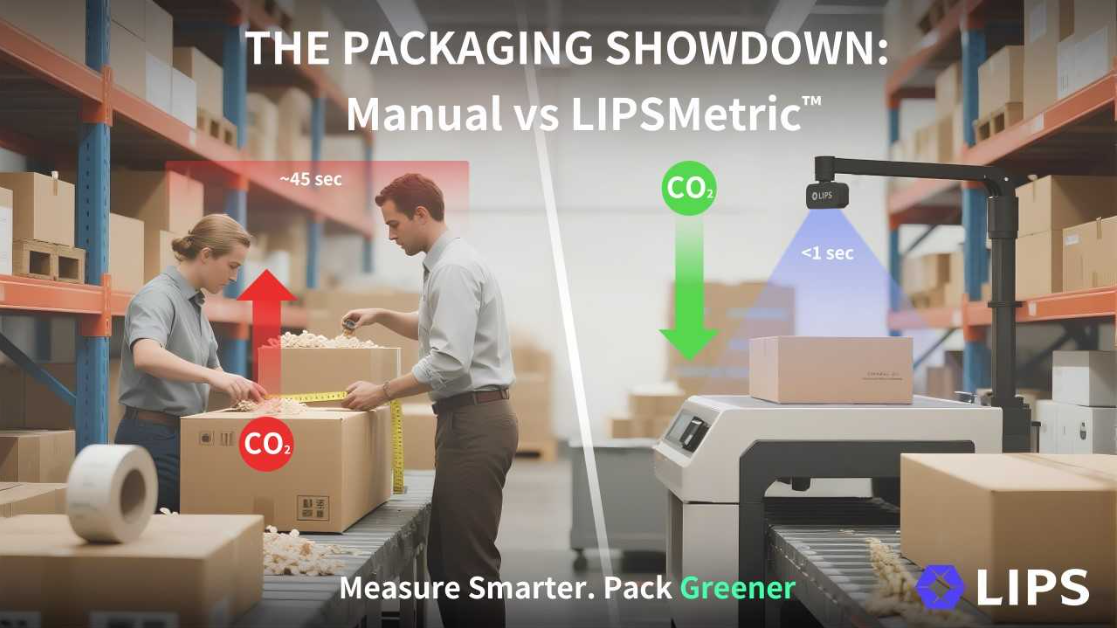

1. Reduce Packaging Waste with Precise Box Sizing

Most packages contain 40-60% empty space, according to Packsize, leading to excess cardboard usage and unnecessary materials like void-fill plastic.

LIPSMetric™ provides fast, accurate dimensioning to ensure right-sized packaging every time. Studies show custom boxes can reduce waste by 40-60%, saving both materials and costs.

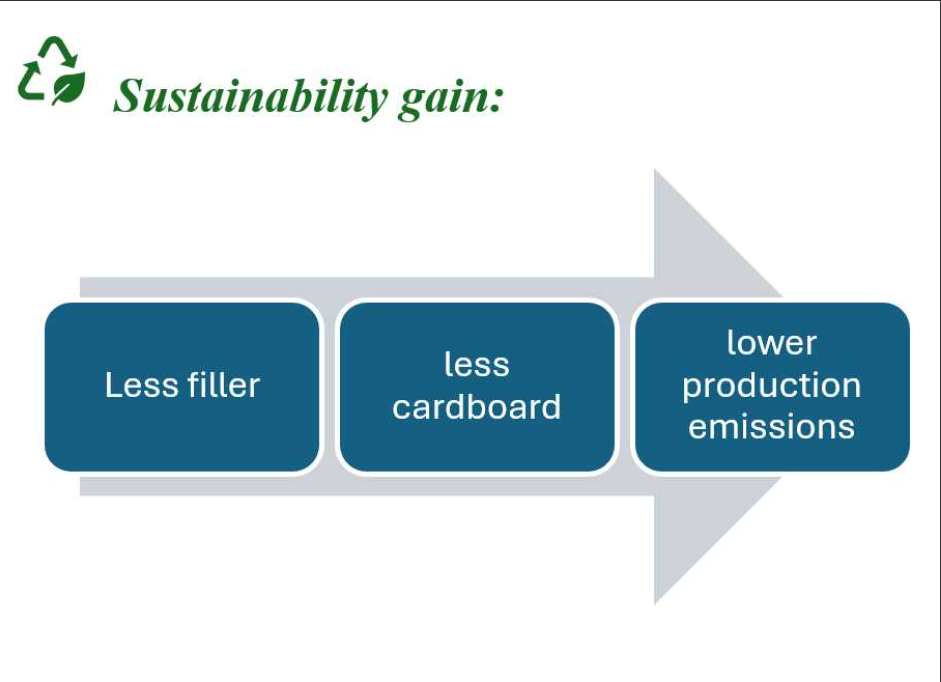

2. Optimize Freight Loading to Cut Emissions

Transport inefficiencies represent a hidden carbon cost in logistics operations. Shipping containers are around 24% underutilized, leading to millions of tons of avoidable CO₂ annually.

By providing accurate volumetric data, LIPSMetric™ enables better pallet and container space utilization.

3. Avoid Dimensional Weight Surcharges

Carriers enforce dimensional weight billing, charging by volume when packages exceed size thresholds. Even minor measurement errors of 3-4 cm can increase costs by $10-$15 per parcel.

LIPSMetric™ accurately measures to the millimeter, preventing costly surcharges and aligning packaging practices with sustainability goals.

4. Enable Reusable & Circular Packaging Systems

Reusable packaging systems (e.g., totes, returnable bins) depend on precise sizing to function efficiently. LIPSMetric™ integrates with ERP/WMS systems to guide reusable packaging selection, reduce damage, and support circular logistics.

LIPSMetric™: Comprehensive Green Logistics Solution

| Feature | Sustainability Benefit |

|---|---|

| Sub-second accuracy | Cuts overpacking and reduces rework |

| API/ERP integration | Automates sustainable packaging decisions |

| Compact edge-AI devices | Minimal power use and hardware footprint |

| SDK flexibility (ST110d, ST130e) | Custom integration for circular/logistics systems |

| Plug-and-play (ST115b) | Fast, low-friction setup for small operations |

| Mobility (Handheld HA115a) | Onsite dimensioning reduces travel and indirect emissions |

Building a Greener Logistics Future with LIPSMetric

Smart dimensioning goes beyond operational efficiency, it drives material savings, emissions reduction, and packaging circularity. LIPSMetric™ enables this by combining speed, precision, and sustainability a comprehensive solution.

The path to sustainable logistics begins with accurate measurement and intelligent decision-making. By implementing precise parcel dimensioning technology, we can achieve meaningful environmental impact while maintaining operational excellence and cost effectiveness.

For detailed technical specifications and implementation guidance, visit our LIPSMetric dimensioning solution page for solution details or inquire at info@lips-hci.com to start your sustainability journey today.

Frequently asked questions for LIPSMetric™ parcel dimensioning

1. How accurate are LIPSMetric™ parcel dimensioning measurements?

LIPSMetric™ delivers millimeter-accurate measurements with sub-second processing speed, preventing the costly measurement errors of 3-4 cm that can trigger $10-$15 dimensional weight surcharges per parcel.

2. How much packaging waste can dimensioning technology reduce?

Studies demonstrate that precise dimensioning and right-sized packaging can reduce waste by 40-60% by eliminating excess cardboard and unnecessary void-fill materials like plastic.

3. Can LIPSMetric™ integrate with existing warehouse management systems?

Yes, LIPSMetric™ offers comprehensive API and ERP integration capabilities, allowing seamless incorporation into existing warehouse management systems for automated sustainable packaging decisions.

4. How does accurate dimensioning prevent dimensional weight charges?

Carriers enforce dimensional weight billing, charging by volume when packages exceed specific thresholds. LIPSMetric™’s millimeter-accurate measurements prevent even minor measurement errors of 3-4 cm that can increase costs by $10-$15 per parcel.

5. What sustainability benefits does parcel dimensioning provide?

Parcel dimensioning drives sustainability through four key areas: reducing packaging waste by 40-60%, optimizing freight loading to cut emissions, avoiding dimensional weight surcharges that encourage oversized packaging, and enabling efficient reusable and circular packaging systems.

6: What makes LIPSMetric™ suitable for sustainable logistics operations?

LIPSMetric™ combines speed, precision, and sustainability features including sub-second accuracy, minimal power consumption through compact edge-AI devices, and comprehensive integration capabilities that eliminate overpacking and reduce operational rework.

References :